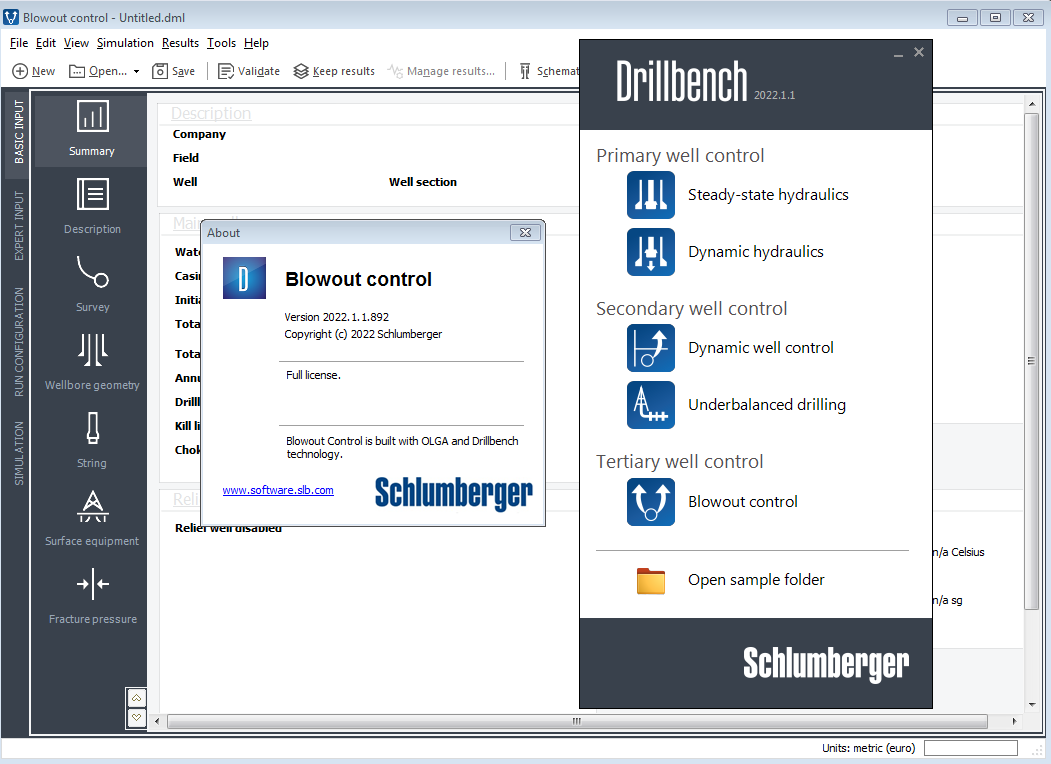

شبیه سازی حفاری | Drillbench 2022.1

Simulations performed in Drillbench dynamic drilling simulation software are key feature to replicate a real drilling operation and provide accuracy not possible with simpler steady-state models. Drillbench software provides a user-friendly tool that targets all drilling engineers involved in challenging wells. The software is built around the well-control workflow, covering pressure control, well control, and blowout control.

Recent enhancements

Integration of well paths directly from the Petrel platform.

Reading pore and fracture pressure from the Techlog platform.

Support for dual gradient drilling with a subsea pump.

Improved modeling of managed pressure drilling.

Strengthened dynamic surge and swab calculations.

Rigsite Kick—a standardized kick sheet for operational rigsite use, based on robust well control modeling and simulation.

The new Drillbench 2022.1 contain general improvements and fixes valid for all applications. In addition to the upgrade of the application platform, there are also many application specific improvements and fixes.

New Graphical Profile

Drillbench 2022 uses a new graphical profile that is better adopted to new hardware. The intention is to improve the appearance on different types of monitors and displays from projectors to large, high resolution monitors.

Upgraded interface components and development tools

Drillbench development tools, compilers and thirdparty components have been upgraded to perform and display better with current versions of Windows. The newer components includes upgrades and bug fixes that adds to an improved appearance and performance of Drillbench 2022 compared to previous versions.

Improved Blowout Control

Many important changes has been made in the new Blowout Control that improves consistency and accuracy in order to provide even more value to our customers. A smoother installation and user administration process will also make the user experience much nicer with the new version compared to previous versions.

New OLGA engine

The OLGA engine has been upgraded to current OLGA 2021.1. A huge effort goes into improving the OLGA engine yearly – and in particular features needed for solving complex drilling related issues.

Performance

The simulations performed in a blowout scenario represent a quite heavy numerical solution, and may result in performance problems. Improved performance has therefore been a key focus area for many years. There are many

factors contributing to the overall performance improvement we are observing, but the most important are:

• Improved and optimized the internal communication between application and engine as OPC has been replaced with ZeroMQ.

• Improved grid definition tailored to drilling scenarios, avoiding small grid cells that sets unnecessary constraints in time step and consequently speed

• Applying smart assumptions and limitations that are fully acceptable and tailored to drilling scenarios

• Preparing simulation files, removing unused elements

• Performance improvements achieved by the engine upgrade

• In cases where the small time steps are required to capture particular transient behavior, the time step control speeds up to optimum as soon as the transient period is over and the same accuracy can be achieved with larger time steps. This feature has been significantly improved since previous version. In total, these improvements gives up to 10 times faster simulations than previous versions. The improvement observed will differ from case to case, depending on the case complexity.

Improved mud density handling

The handling of mud density for oilbased and synthetic systems has been improved. A new model has been used that is consistent for all PVT options has been implemented. The new model has solved a problem seen in modelling mud density and ECD for some drilling fluids.

As part of this work a bug was identified in cases with many fluid configurations. In some cases a the table indexing was wrong resulting that a different fluid than the selected, was used in circulation.

Communication Olga Drilling Service

The communication protocol between the interface and OLGA drilling service has been upgraded from OPC to ZeroMQ. This adds to the speed up and improved performance, but the most important is that it allows running the Olga Drilling Service without local admin access.

تیم PetroTools آخرین نسخه این نرم افزار را برای شما ارائه می دهد. جهت تهیه نرم افزار با استفاده از منوی خرید با ما در تماس باشید

For buy software, Please contact us via buy menu

O-Sense

O-Sense