آنالیز پایداری دیواره چاه | STABView 3.8

STABView - a software program for wellbore stability, sand production, lost circulation and discontinuity slip risk analysis. STABView was developed for technical drilling, completion, production and exploration personnel to conduct rapid parametric analyses for a wide range of near-wellbore integrity problems. Efficient, rapidly converging, analytical and semi-analytical algorithms are used to solve the fundamental equations that describe the stresses, pore pressures, and temperature distributions for near-wellbore problems. Additional information regarding these models is included in Section 4 of this manual.

Problems You Can Analyze with STABView:

1.2.1 Drilling Applications

1. Optimize a well casing program.

2. Select optimal drilling and completion fluids.

3. Optimize mud chemistry to inhibit clay swelling.

4. Avoid stuck pipe or coiled tubing.

5. Reduce reaming and cleaning time.

6. Avoid drillstring fatigue and failure.

7. Reduce the risk of lost circulation.

8. Improve directional control.

9. Assess suitable candidates for underbalanced drilling.

10. Model hydraulics with realistic enlarged hole sizes.

11. Interpret formation leak-off and in-situ stress tests.

12. Predict borehole deformations or squeezing behavior.

13. Predict borehole enlargement in permafrost zones.

1.2.2 Well Control Applications

14. Assess near-wellbore stress and pore pressure conditions.

15. Evaluate hydraulic fracturing options to intersect a flowing well.

1.2.3 Formation Evaluation Applications

16. Avoid stuck or damaged DST and logging tools.

17. Avoid log interpretation problems due to hole ellipticity.

18. Avoid logging limitations in OBMs.

19. Back-analyze in-situ stresses and pore pressures.

20. Evaluate the most permeable natural fracture sets.

1.2.4 Completions Applications

21. Determine well candidates for barefoot completions.

22. Reduce unnecessary cased and perforated completions.

23. Evaluate expandable sand screen (ESS) candidates.

24. Avoid poor cement integrity.

25. Eliminate the risk of fracturing away cement.

26. Optimize a perforating program.

27. Increase perforation penetration.

28. Eliminate unnecessary sand control.

29. Evaluate the need for a gravel pack in weak sandstones.

30. Evaluate casing deformations or failures due to formation shearing.

31. Design cavity completions for coalbed methane wells.

1.2.5 Stimulation Applications

32. Determine the maximum injection pressure for matrix stimulation.

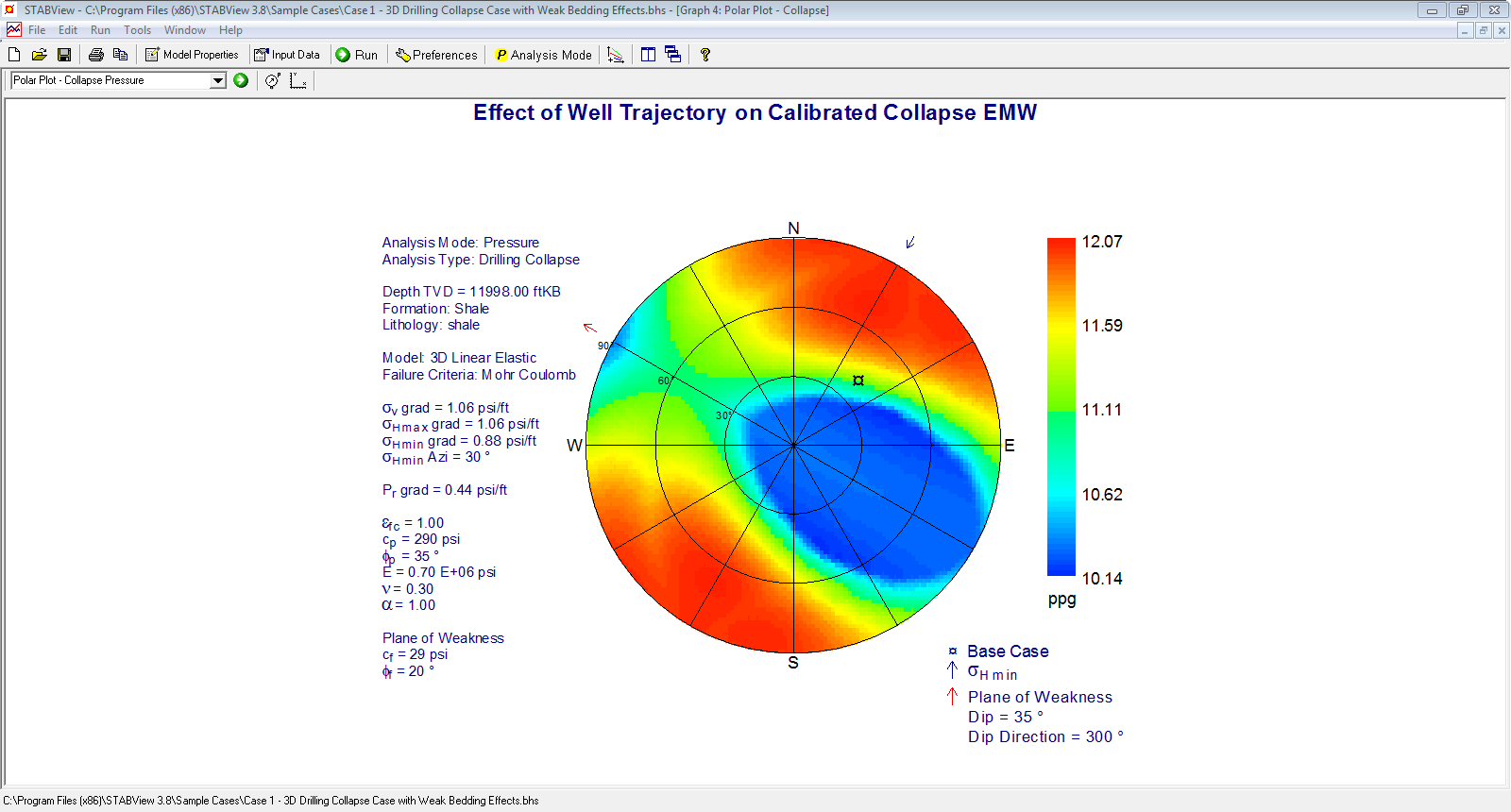

33. Evaluate the effects of hole trajectory on induced fractures.

34. Assess the potential for linking up induced hydraulic fractures.

35. Estimate the pressure required to re-open or cause slip on natural fractures and faults.

1.2.6 Production Engineering Applications

36. Reduce undesirable sand production.

37. Avoid openhole collapse under drawdown conditions.

38. Optimize drawdown to avoid sand production from perforations.

39. Reduce wellbore skin due to unnecessary sand control.

40. Assess the loading on a liner due to sand deformations.

41. Evaluate the risk of mechanical formation damage.

42. Design to collapse sand and pack it around liners or screens.

43. Optimize the performance of gas storage wells by reducing skin.

44. Design for sand production in heavy oil reservoirs (CHOPS).

45. Reduce water production from induced hydraulic fractures.

46. Calculate the maximum waterflood injection pressure to avoid fracturing.

47. Assess thermally-induced fracturing during waterflooding.

1.2.7 New and Novel Applications

48. Design wells for greenhouse gas sequestration.

49. Optimize horizontal directional drilling for pipelines.

50. Evaluate slurry and solid waste injection options.

تیم PetroTools آخرین نسخه این نرم افزار را برای شما ارائه می دهد. جهت تهیه نرم افزار با استفاده از منوی خرید با ما در تماس باشید

For buy software, Please contact us via buy menu

O-Sense

O-Sense