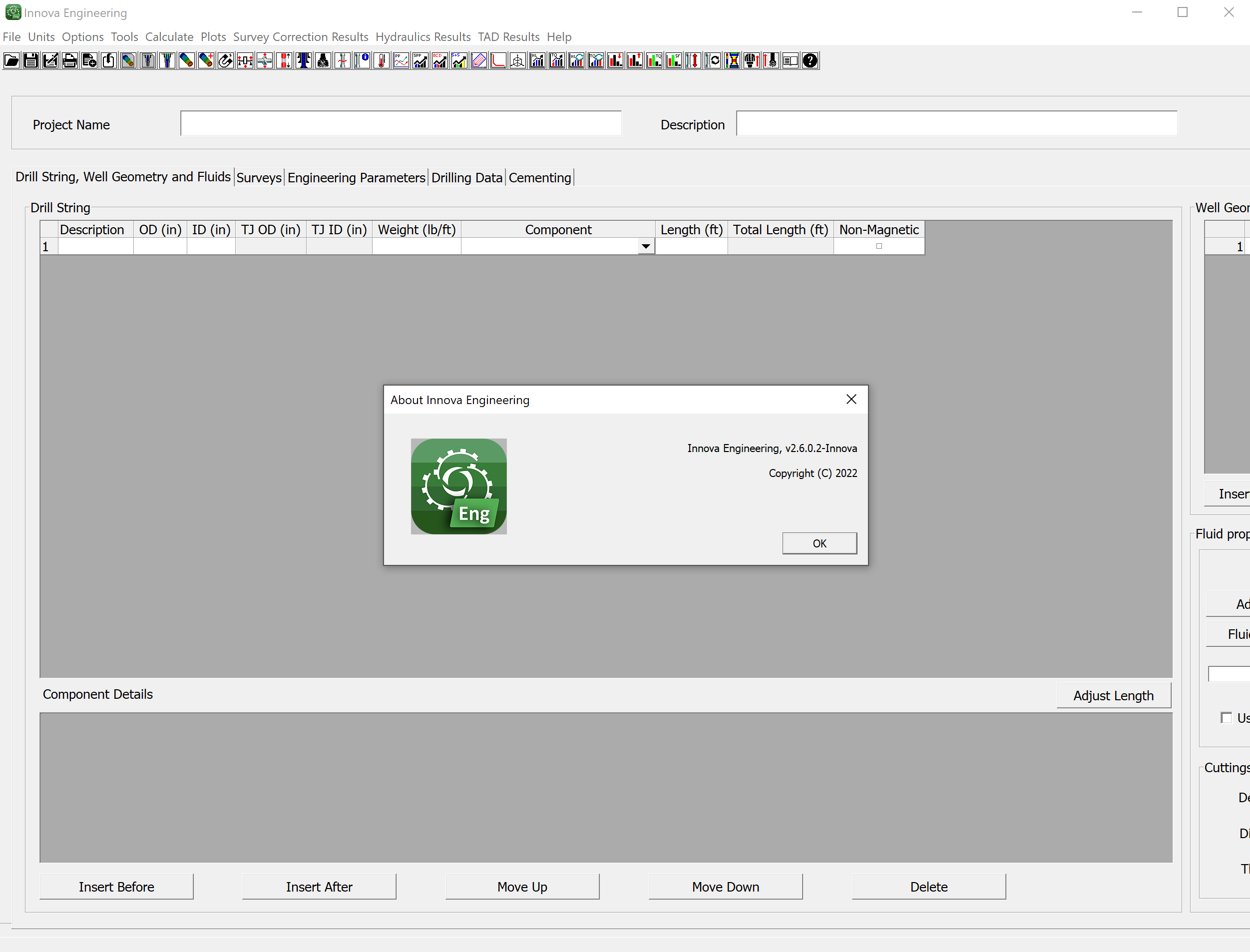

مهندسی حفاری | Innova Engineering 2.6.0.2

Innova Engineering is Intuitive and powerful drilling software application designed to aid Operators and Service Company's deal with the challenges todays drilling industry presents. From the onshore drilling engineering team to the well placement specialists on the rig, Innova provides a complete solution in one simple and easy to use package.

Features:

Remote Directional Drilling & RTOC features

Directional Drilling Dashboard

Remote data fetch

Real Time Data Exchange

Well Trajectory Design

Real Time Anti-Collision

Wellbore Visualization

Survey Management

Geomagnetic Modelling

Integrated Geo-steering functionality

Integrated Daily Reporting

Database Analytics Tool

Well AFE Designer

Torque & Drag Analysis

Hydraulics & Hole Cleaning Analysis

Survey Correction

BHA Analysis & SAG Correction

Magnetic Interference Calculator

Casing Standoff & Centralizer Spacing

Jar Placement

Cementing

Casing Design

Well Control

Torque & Drag

Latest soft string model with stiffness correction factor

Model Viscous Drag, additional side force due to buckling & Contact Surface Correction

Conservative (Unloading) & Standard (Loading) buckling Models

Calculate T&D for multiple rig operations simultaneously Tripping In / Out, Rotating On / Off Bottom, Sliding and Reaming

Ability to model for both pumps on and pumps off and account for string differential pressure

Calculate Sinusoidal and Helical buckling limits

Full support for casing, liner, tubing & drilling assemblies

Full support for complex 3D directional wells

Friction factor sensitivity analysis for unlimited number of friction factors, or single calculation

Models casing flotation / drill string fill

Model effects of bow spring centralizers on torque and drag

Friction reduction devices (Non-rotating drill pipe protectors) can be modelled

Calculates expected pipe stretch and torque induced pipe twist

Elemental (snapshot) view available for all calculations

Calculate side forces & casing wear for all operations

Drill string fatigue prediction

Real time data can be modelled & displayed alongside the calculated data in order to back calculate real time friction factor

Actual and apparent WOB and overpull calculations, visualize how much overpull / WOB is experienced at the bit for a given value seen at surface. Useful for determining trip / overpull margins and for setting packers & liner hangers

Casing Standoff & Centralizer Spacing Calculation. Use to optimise standoff and achieve proper zonal isolation

Ability to model expandable liners including max pull, pull at cone, expected expansion hookload as well as outer & inner string running loads

Ability to model different materials such as Aluminium, Titanium as well as steel

Ability to model Air Drilling

Option to select the fluid level in the wellbore

Hydraulics & Hole Cleaning

Support for multiple hydraulic models:

Bingham Plastic

Power Law

Herschel Bulkley

Robertson Stiff

Calculated Outputs:

Standpipe Pressures

ECD: cuttings loaded and clean hole

Surge and Swab

Complete set of hole cleaning outputs:

Annular Velocity Profile

Cuttings Carrying Index (CCI)

Cuttings %

Minimum Flowrate required for good hole cleaning (sensitivity analysis for ROP)

Options for single calculation or sensitivity analysis for unlimited number of flowrates and tripping speeds simultaneously

Full support for riser-less / dual gradient drilling

Split flow modelling for complex BHAs with multiple hole openers / under reamers / circulating subs

Incorporate data gathered at the well site into the hydraulics model and overlay the real-world data and the theoretical hydraulics model

Enter multiple pore pressures & fracture gradients and plot against modelled data

Surge and swab calculations can be calculated for any reference:

Bit

Casing Shoe

Bottom Hole

Any User Defined depth

Surge and swab model can also include the effects of pipe acceleration, gel strength, coil tubing operations such as continuous tripping and continuous circulation

Model the effect of stabilizers and casing centralizers

Quick bit hydraulics calculator, determine bit pressure losses and impact force without having to setup a complete project

Pump Pressure Safety Factor: Option to allow the user to increase the SPP by a specified percentage

Ability to model air drilling

Ability to apply a back pressure for MPD operations

Ability to include additional riser boost flow rate

Survey Correction

Correct raw MWD surveys for Z axis magnetic interference with latest short collar correction algorithm

QC raw MWD surveys for G total, B total and SCC with user definable limits

Well path magnetic interference analysis, calculate the expected error in azimuth for a given amount of non mag spacing. Fully supports intermediate steel above and below the MWD sensor or both

Multi Station Analysis (MSA) can be used to calculate an optimal bias and scale factor for XYZ magnetometers and accelerometers

No need to enter a separate BHA for magnetic interference or SAG correction. All calculations can be done from one BHA which greatly simplifies data entry.

Option to include inclination weighting on least squares fit (LSQ) calculation

Optimize the non mag spacing requirements and determine the best survey correction method for a give well trajectory / BHA

Full support for the following Survey Calculation Methods:

Minimum Curvature

Radius of Curvature

Tangential

Balanced Tangential

Supports survey interpolation for both MD and TVD, results can be exported to text or Excel

Produce fully customizable plots for both section and plan views and overlay well plan and actual surveys on one chart

QC raw MWD surveys for G total, B total and magnetic dip with user definable limits

BHA Analysis & SAG Correction

Survey SAG correction algorithm, to correct survey inclinations for BHA deflections

Can model bent motors and rotary steerable systems

Rotary BHA modelling to aid in build / walk rate predictions (equilibrium rate)

Predicted build / walk Rate for Sliding based on motor bend, hole size and Bit Formation Index

Predicated build / walk rates for both push and point the bit rotary steerable systems

Take in to account bit aggressiveness and bit type (PDC, rollercone)

Vibration analysis calculates Critical RPM

Magnetic Interference Calculator

BHA magnetic Interference Calculator Module

Well path magnetic interference analysis; calculate the expected error in azimuth for a given amount of non-mag spacing. Fully supports intermediate steel above and below the MWD sensor or both

Calculate non-magnetic spacing requirements and azimuth error for any well trajectory and BHA configuration

Casing Standoff & Centralizer Spacing

Model rigid and bow spring centralizers

Automatically optimize centralizer placement based on a desired standoff value

Calculate deflection at centralizers and mid joint

Ability to model bow spring running and restoring forces

Model the additional side force created by the compression of bow spring centralizers

One click standoff summary report, including tabulated results accompanied by standoff, side forces and hookload charts

Jar Placement

Calculates neutral point road map which shows WOB to avoid at every depth along the well path

Calculates pump open force

Model the impact / impulse of all types of jars, accelerators & intensifiers

Optimize the hammer length / jar type to maximize impulse / impact

Calculates weight above and below jar when vertical in air and mud

Calculates weight above and below jar at bottom hole location in air and mud

Cementing

Cementing Schematic Animation gives a visual representation of the well geometry, string and fluids at any given stage in the cement job

Calculate annular pressure, equivalent circulating density and pump pressure during cementing operations

User definable Pumping Schedule

Ability to model calculations with inner string

Select from Bingham, Power Law, Herschel Bulkley or Robertson Stiff Hydraulics Models

Calculate capacities and displacements

Calculate Top Down, Bottoms up and Full Circulation times

Well Control

Determine kick tolerance and perform sensitivity analysis to show how the kick tolerance changes throughout the section and the effect of mud weight changes

Calculate MASP, MAASP in order to determine surface pressure control equipment requirements

Quickly determine required kill mud weight and pumping schedule to kill the well

تیم PetroTools آخرین نسخه این نرم افزار را برای شما ارائه می دهد. جهت تهیه نرم افزار با استفاده از منوی خرید با ما در تماس باشید

For buy software, Please contact us via buy menu

O-Sense

O-Sense